First-of-its-kind system eradicates residual dairy barn methane in large-scale trial

Plus, technology for the multisite dairy

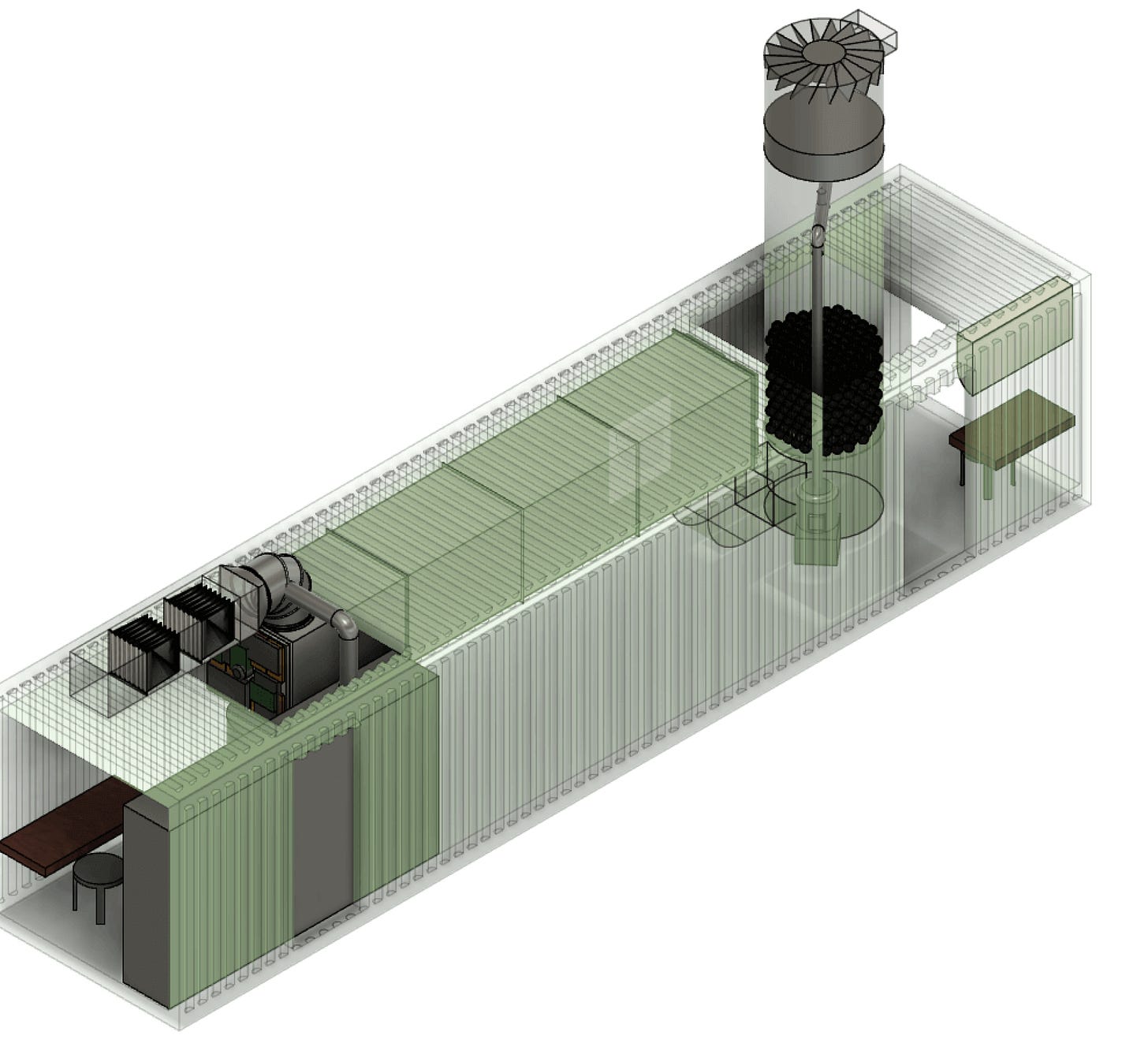

A groundbreaking field demonstration of a new technology has successfully proven to effectively eliminate diluted methane emissions from commercial dairy barns. The field trial of the Methane Eradication Photochemical System (MEPS) represents the first real-world validation of a scalable technology capable of eradicating methane emissions from livestock barn air.

The system uses a novel patented gas-phaseal process to break down methane using chlorine radicals activated by UV LED arrays. As a completely noninvasive solution, MEPS does not affect cows, cow comfort, milk production or barn operations, and the technology’s modular design allows for deployment at variously sized dairy barns.

The trial was conducted at a dairy farm in Denmark, where the unit – housed in a standard 40-foot shipping container – processed air samples from a 250-cow, open-sided dairy barn.

“The system successfully oxidized methane from dairy barn ventilation air across varying concentration levels, proving that it can deliver consistent performance under real agricultural conditions with co-pollutants present,” says Matthew S. Johnson, co-founder and chief science officer at Ambient Carbon, the owner of the technology tested. “Across the initial tests, up to 90 percent of inlet air methane was eradicated over a methane concentration range of 4.3 ppm to 44 ppm.”

In addition to destroying methane, the system also removed ammonia and other odors from the dairy barn, while also generating fertilizer as a byproduct that can be utilized to decrease the farm’s operating costs.

Danone North America provided financial support for the trial.

Learn more about the company behind the trial here.

Technology for the multisite dairy

Tune in Aug. 26 to hear how technology is helping California dairyman Rob Diepersloot manage multiple facilities in two different states. He’s also launched a consumer colostrum supplement brand. Hear how and why he dove into the consumer market during the live event.

‘Individualized data is powerful’

I found this quote from one researcher about what he learned when researching technology applications on farm interesting:

“Not all farms are the same. There’s huge variation between farms – different diets, different conditions, not to mention different technology being used – so the threshold for when a cow needs help will vary too. That’s why individualized data is so powerful.”

Read more about his research into using activity monitors to improve hyperketonemia detection and early treatment on-farm.

Fodder and invisible fences

Check out what this cattle operation is doing to use technology to enable less confined feeding in response to their direct-to-market consumers’ concerns.

Read more here.

Dairy profit projections from ZISK

Projected profitability for the next 12 months for two dairy herd sizes INCREASED in recent profit projections from ZISK.

ZISK is a profit projection smartphone app that tracks individual dairy farm profitability based on current CME board prices. Projections for a 1,000-cow dairy producing an average of 80 pounds of milk per cow and a 2,500-cow dairy producing an average of 85 pounds of milk per cow are provided.

12-month dairy farm profit projections (as of Aug. 14, 2025):

1,000-cow dairy = $619,700 (UP about $23,700 since the end of July)

2,500-cow dairy = $2.274 million (UP about $63,000 since the end of July)